SMP Parts started using LINDOFLAMM® flame solutions one year ago for pre-heating high-strength steel. The result has exceeded all expectations so far.

“When I first heard about LINDOFLAMM, I have to admit it sounded too good to be true,” says SPM’s Head of Welding, Thomas Sandin. “But it works – and it’s saving us time and money.”

SMP Parts - more than 30 years experience

SMP Parts AB in Hudiksvall, Sweden produces high-quality equipment and tools for excavators and backhoe loaders. With more than 30 years’ experience in the industry, SMP offers one of the market’s broadest assortments of excavating accessories, quick attachments, buckets and similar tools.

As SMP’s products operate in some of the toughest environments on the planet, they need to be made from material that is robust and durable. This is why SMP uses wear-resistant Hardox steel from leading Swedish steel producer SSAB.

Accurate preheating is crucial

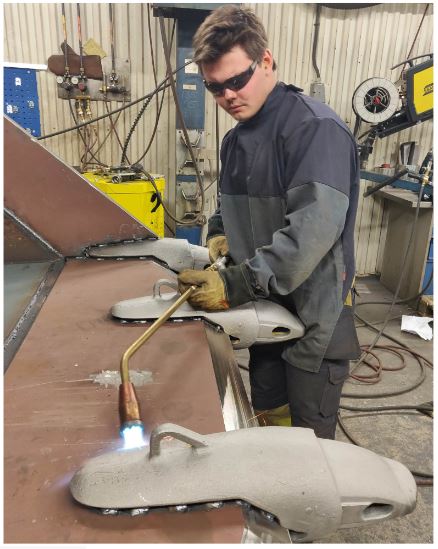

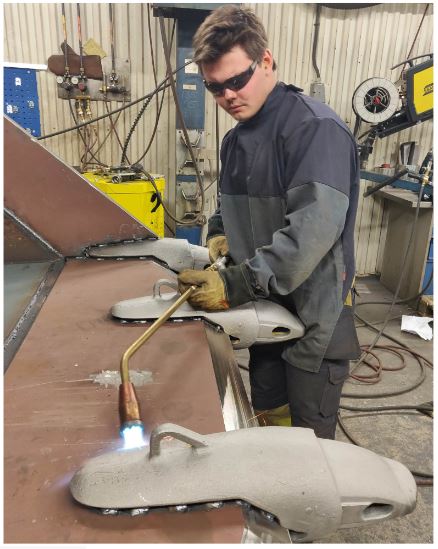

Hardox is high-strength steel and it needs to be heated all the way through, to a consistent temperature, before welding, so it doesn’t crack. Sandin explaings why preheating is so important when working wiht HARDOX. “Since introducing LINDOFLAMM, we can do this more quickly and accurately than before.”

In the past, SMP’s preheating process had involved using a handheld, propane burner. This could take up to 45 minutes and the burner did not only heat the steel, it also raised the temperature in the entire room.

Specialists involved

The existing process may not have been ideal but, before replacing it, SMP Parts had to make sure the any new solutions they introduced would not have a negative impact on either the Hardox or, most crucially, the quality of their end product. Oskar Thorstensson and Mikael Reinberth from the Manufacturing Technology group at SSAB were brought in, along with Linde’s welding specialists, to help set up the new process and ensure a smooth transition.

Several tests led to the a new preheating process

“At SSAB we work closely with our customers with both technical support and helping them develop their products or processes,” says Reinberth.“The need for preheating is linked to how hard the steel is and the type of alloy. In SMP’s case, we had to make sure that the area being cut or welded reached the recommended preheating temperature and that this temperature could be maintained throughout the process,” he adds.

SSAB and Linde carried out a joint test during which they heated up the steel at various distances and temperatures. After that, SSAB tested its hardness. These tests enabled them to identify the ideal parameters, in terms of distance and heating time, and, as a result, SMP’s operators now know exactly what process to follow.

From 45 to 5 minutes

Just over a year after launching the new process, Sandin admits the results have exceeded all his expectations. “Since introducing LINDOFLAMM, a process that used to take 45 minutes now takes about seven minutes and nobody has to stand holding the burner. We just position it and switch it on,” he explains, adding that, by enabling the technicians to spend less time heating and more time welding, SMP has secured considerable time and cost savings.

“We get the results we want three times faster and it’s far better for the working environment since the room doesn’t get as hot as it used to and our operators don’t have to stand in one position,” Sandin concludes.